Information

SUMMUS Xinhe laser ingenuity, details polish high-quality products

2024-12-28

Innovation is an inexhaustible driving force for enterprise development.SUMMUSXinhe LaserFacing traditional weldingprocessLow efficiency,Poor weld quality,Industry pain points such as unsatisfactory welding effect,Introduce high-efficiency, high-quality airtight laser welding equipment, which can achieve high-quality welding results for high-anti-metal materials such as copper and aluminum.

forupsatisfyProduct differentiation weldingDemand.Increase productivity,SUMMUSXinhe Laser increases R & D innovationInvest.For laser welding equipmentperformance improvementcontinueConduct in-depth research, pushoutPremium SV55Pro+Laser welding equipment, with“spaceexpand”Advantages that bringwelding processingThe high degree of flexibility in production allows forspecial weldingProcessing scene.

Premium SV55Pro+Continued on device parametersSV55ProThe basic functions and configuration of the modelCCDweldSurveillance system,canClearly observe the welding position and welding effect, has excellent beam of light quality. On the material, can weld copper, brass,1~7Aluminum alloy,ADC12Aluminum, titanium alloy, stainless steel and other metal materials.

withHIGH STThe difference between the series of other laser welding equipment is that,Premium SV55Pro+laserWelding equipment has an alternativeBed design,welding heightfor50-600mm, welding areafor300mm*300mmThe table surface disc can support360Rotation, just a light turn, you can easily complete the welding task of water-cooled plate waterway mouth and other structures。

It is well known that in the production and welding process of water-cooled plates and liquid-cooled plates, the airtightness welding of the waterway structure cannot be ignored.Premium SV55Pro+Compared to laser welding equipmentSUMMUS SV55ProWith a lower work surfacedesign, making weldingProcessing areaThe scope is larger, and the multi-axis linkage welding equipment with vertical fixture makes the plane welding second-to-space welding, which can weld special parts of higher and longer size workpieces, which can be described as a waterway welding tool.

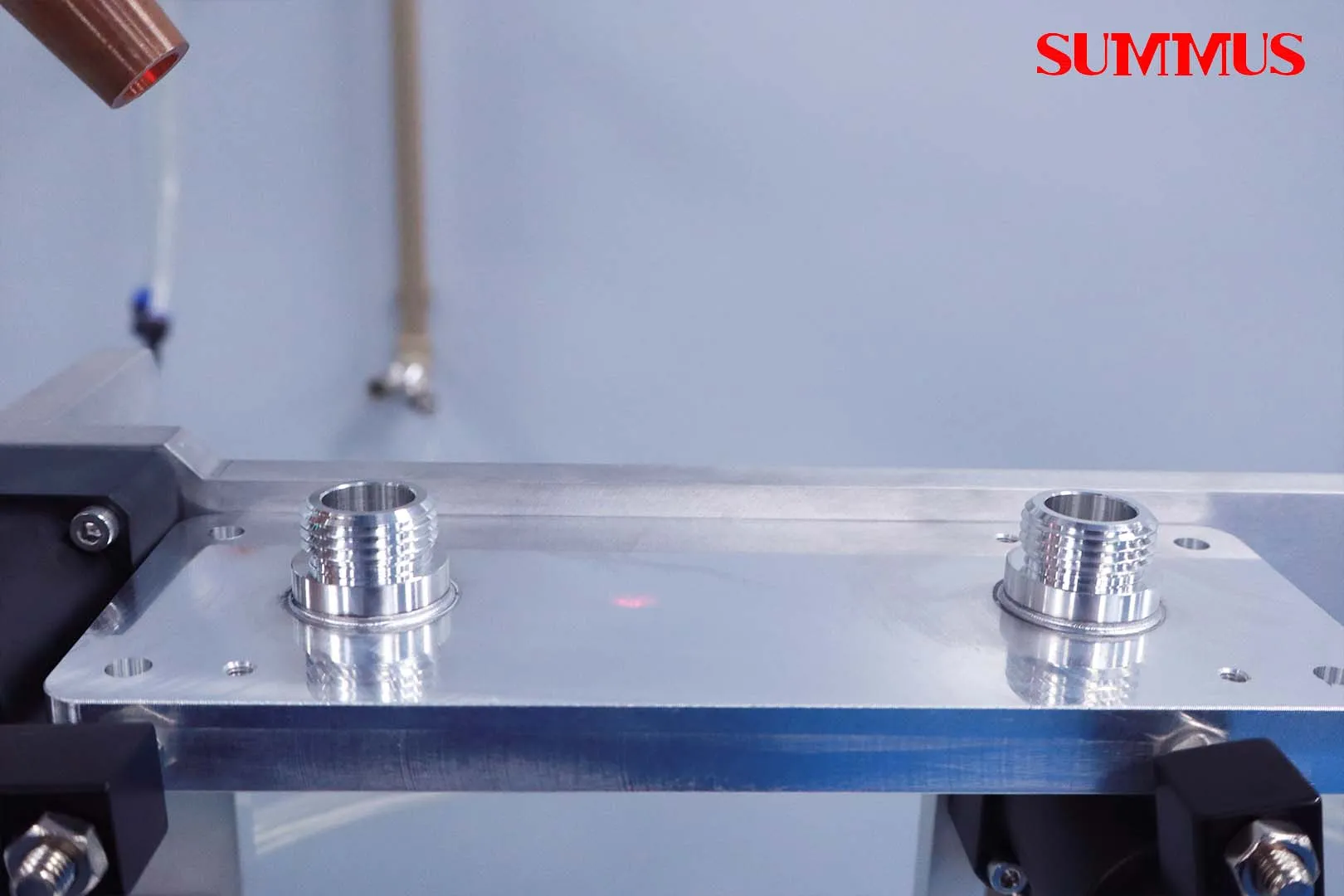

As shown in the picture, this is a long strip-shaped copper water-cooled plate that requires dot welding on one side of the cover plate.Premium SV55Pro+The welding processing area of laser welding equipment can easily accommodate workpieces.Achieve high efficiency and accuracyWelding, fast welding speed, small heat affected zone。This is the welding effect that has just been welded and has not been surface treated.,The weld can be formed once, without repair welding, with high welding accuracy and beautiful appearance of the workpiece.

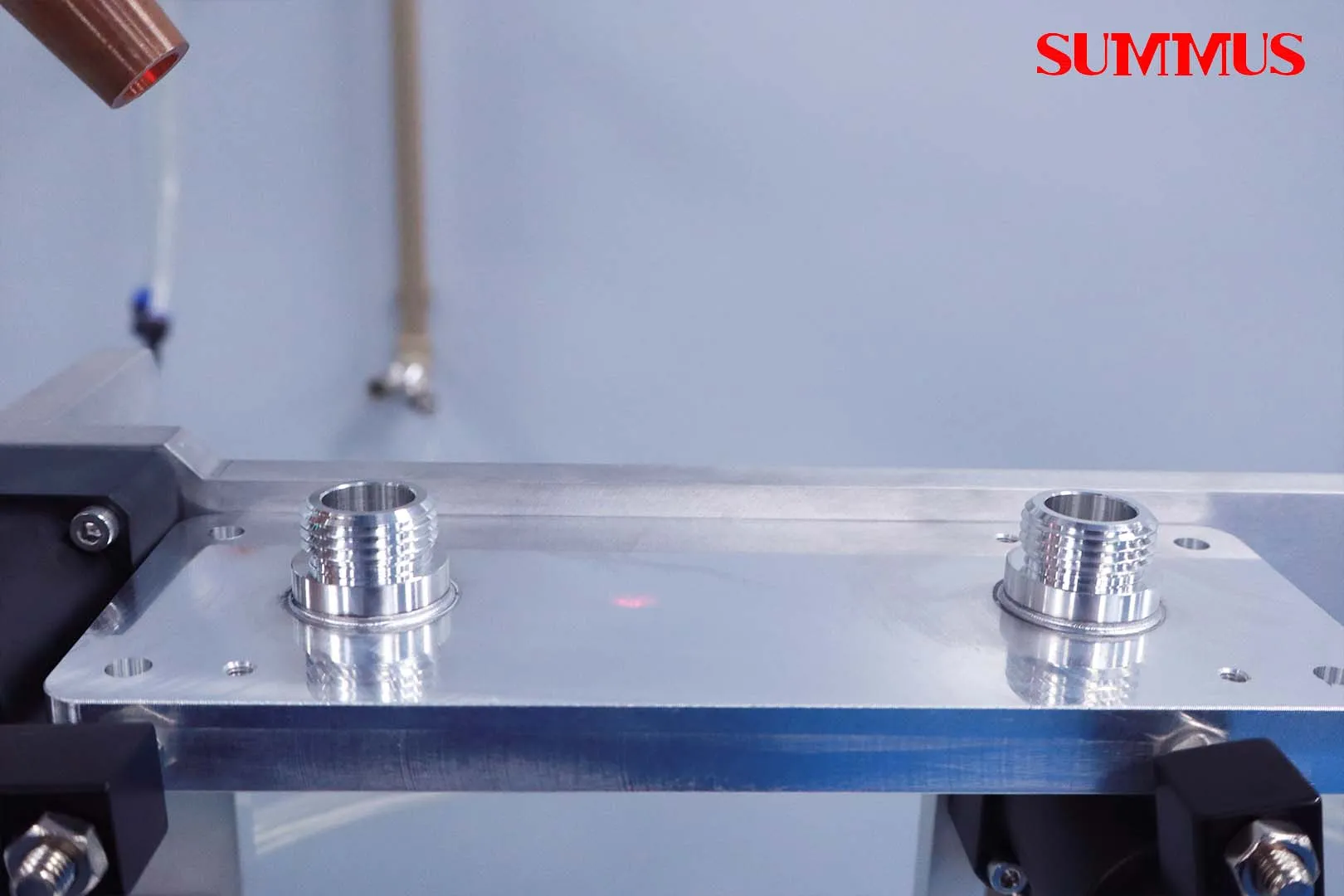

The fixtures of the equipment machine can be disassembled and configured flexibly,easyachieveWelding of water-cooled plate nozzles and special-shaped structural partsIt greatly expands the processing range.Adapt to a variety of product designs, withpowerfulwelding processingAnd capacity.

SUMMUSXinhe Laser focuses on the airtightness welding of cold plate liquid-cooled heat sinks such as water-cooled plates, liquid-cooled plates, soaking plates, and energy storage plates. It treats every step of the welding process with a meticulous and refined attitude, paying attention to every detail, and polishing high-quality products with ingenuity. It constantly pursues more efficient and stable welding effects to ensure the connection strength and sealing of each weld, meeting high-standard product requirements.

Innovation is an inexhaustible driving force for enterprise development.SUMMUSXinhe LaserFacing traditional weldingprocessLow efficiency,Poor weld quality,Industry pain points such as unsatisfactory welding effect,Introduce high-efficiency, high-quality airtight laser welding equipment, which can achieve high-quality welding results for high-anti-metal materials such as copper and aluminum.

forupsatisfyProduct differentiation weldingDemand.Increase productivity,SUMMUSXinhe Laser increases R & D innovationInvest.For laser welding equipmentperformance improvementcontinueConduct in-depth research, pushoutPremium SV55Pro+Laser welding equipment, with“spaceexpand”Advantages that bringwelding processingThe high degree of flexibility in production allows forspecial weldingProcessing scene.

Premium SV55Pro+Continued on device parametersSV55ProThe basic functions and configuration of the modelCCDweldSurveillance system,canClearly observe the welding position and welding effect, has excellent beam of light quality. On the material, can weld copper, brass,1~7Aluminum alloy,ADC12Aluminum, titanium alloy, stainless steel and other metal materials.

withHIGH STThe difference between the series of other laser welding equipment is that,Premium SV55Pro+laserWelding equipment has an alternativeBed design,welding heightfor50-600mm, welding areafor300mm*300mmThe table surface disc can support360Rotation, just a light turn, you can easily complete the welding task of water-cooled plate waterway mouth and other structures。

It is well known that in the production and welding process of water-cooled plates and liquid-cooled plates, the airtightness welding of the waterway structure cannot be ignored.Premium SV55Pro+Compared to laser welding equipmentSUMMUS SV55ProWith a lower work surfacedesign, making weldingProcessing areaThe scope is larger, and the multi-axis linkage welding equipment with vertical fixture makes the plane welding second-to-space welding, which can weld special parts of higher and longer size workpieces, which can be described as a waterway welding tool.

As shown in the picture, this is a long strip-shaped copper water-cooled plate that requires dot welding on one side of the cover plate.Premium SV55Pro+The welding processing area of laser welding equipment can easily accommodate workpieces.Achieve high efficiency and accuracyWelding, fast welding speed, small heat affected zone。This is the welding effect that has just been welded and has not been surface treated.,The weld can be formed once, without repair welding, with high welding accuracy and beautiful appearance of the workpiece.

The fixtures of the equipment machine can be disassembled and configured flexibly,easyachieveWelding of water-cooled plate nozzles and special-shaped structural partsIt greatly expands the processing range.Adapt to a variety of product designs, withpowerfulwelding processingAnd capacity.

SUMMUSXinhe Laser focuses on the airtightness welding of cold plate liquid-cooled heat sinks such as water-cooled plates, liquid-cooled plates, soaking plates, and energy storage plates. It treats every step of the welding process with a meticulous and refined attitude, paying attention to every detail, and polishing high-quality products with ingenuity. It constantly pursues more efficient and stable welding effects to ensure the connection strength and sealing of each weld, meeting high-standard product requirements.