Information

Xinhe laser welding equipment core technology

2024-08-07

Xinhe Laser——Solutions and Features

Adopting annular spot technology, it can minimize defects such as cracks and pores, and meet national standards.(GB/T 22085)BGrade standard, the obtained weld has good pressure resistance and good fatigue durability.

High welding efficiency, low energy consumption and environmental protection;

Higher welding line energy and smaller welding heat affected zone, smooth and beautiful weld appearance;

Automatic control, non-contact processing, high stability.

Xinhe Laser——Aluminum alloy welding process

Xinhe Technology -- Ring spot technology:

Welding is done by using an annular spot, and the ratio of the annular and central lasers is used to control the temperature gradient and reduce cracks.Stirring

can helpExpel gas and reduce welding porosity.

Xinhe Laser - Laser welding keyhole formation process

Xinhe Laser——Welding process advantages

Welding process advantage 1: 1, can realize aluminum alloy self-melting or wire-filling welding, zero spatter or low spatter 2, welding speed1-3m/min, is the friction stir welding5-10Times faster 3, small deformation, no need for shaping or micro-shaping after welding 4, the surface cleaning amount is much lower than that of friction stir welding, only cleaning is required 0.2mmabout 5, Simple fixtures, low cost and strong versatility 6, low splash, no pollution to the faucet and flow channel (no faucet protection required)

|

|

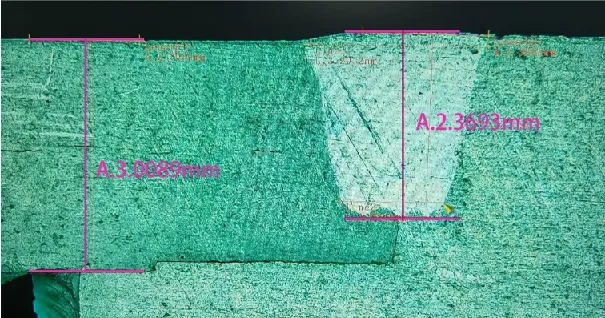

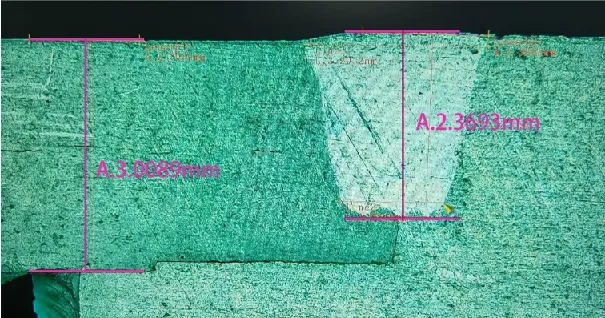

Welding process advantage 2: 1, The weld metallographic structure shows no pores or cracks 2, High strength of welded joints 3, the molten pool shape is stable and presentsUType, anti-airtight pressure, anti-fatigue

4, The equipment is light and occupies a small area |

|

Xinhe Laser——Summary of the advantages of laser welding

High precision:Laser welding can achieve high-precision welding by controlling the focus of the laser beam.PointThe welding depth and width can be precisely controlled by adjusting the position and power.

No contact:Laser welding is a non-contact welding technology. The laser beam does not need to be directlytouch

The welding process can be completed on the workpiece surface, reducing the risk of deformation of the workpiece.

high speed:Laser welding has a fast welding speed. The high energy density of the laser beam can quicklyspeedHeating and cooling of metal materials, thereby shortening welding cycle.

This is for large-scaleMold production and efficientThe production line is very heavyIt can improve production efficiency and reduce costs.

Small heat affected zone:The heat affected zone of laser welding is smaller than that of other traditional welding methods.The high energy density of the laser beam and the fast welding speed make laser welding

Minimizes heat spread around the weld areaThis helps maintain the original quality of the workpiece.

Performance and material properties.

Using laser welding machines to process workpieces can improve work efficiency. The finished workpieces have beautiful appearance, small welds, large welding depth and high welding quality.

Xinhe Laser——Solutions and Features

Adopting annular spot technology, it can minimize defects such as cracks and pores, and meet national standards.(GB/T 22085)BGrade standard, the obtained weld has good pressure resistance and good fatigue durability.

High welding efficiency, low energy consumption and environmental protection;

Higher welding line energy and smaller welding heat affected zone, smooth and beautiful weld appearance;

Automatic control, non-contact processing, high stability.

Xinhe Laser——Aluminum alloy welding process

Xinhe Technology -- Ring spot technology:

Welding is done by using an annular spot, and the ratio of the annular and central lasers is used to control the temperature gradient and reduce cracks.Stirring

can helpExpel gas and reduce welding porosity.

Xinhe Laser - Laser welding keyhole formation process

Xinhe Laser——Welding process advantages

Welding process advantage 1: 1, can realize aluminum alloy self-melting or wire-filling welding, zero spatter or low spatter 2, welding speed1-3m/min, is the friction stir welding5-10Times faster 3, small deformation, no need for shaping or micro-shaping after welding 4, the surface cleaning amount is much lower than that of friction stir welding, only cleaning is required 0.2mmabout 5, Simple fixtures, low cost and strong versatility 6, low splash, no pollution to the faucet and flow channel (no faucet protection required)

|

|

Welding process advantage 2: 1, The weld metallographic structure shows no pores or cracks 2, High strength of welded joints 3, the molten pool shape is stable and presentsUType, anti-airtight pressure, anti-fatigue

4, The equipment is light and occupies a small area |

|

Xinhe Laser——Summary of the advantages of laser welding

High precision:Laser welding can achieve high-precision welding by controlling the focus of the laser beam.PointThe welding depth and width can be precisely controlled by adjusting the position and power.

No contact:Laser welding is a non-contact welding technology. The laser beam does not need to be directlytouch

The welding process can be completed on the workpiece surface, reducing the risk of deformation of the workpiece.

high speed:Laser welding has a fast welding speed. The high energy density of the laser beam can quicklyspeedHeating and cooling of metal materials, thereby shortening welding cycle.

This is for large-scaleMold production and efficientThe production line is very heavyIt can improve production efficiency and reduce costs.

Small heat affected zone:The heat affected zone of laser welding is smaller than that of other traditional welding methods.The high energy density of the laser beam and the fast welding speed make laser welding

Minimizes heat spread around the weld areaThis helps maintain the original quality of the workpiece.

Performance and material properties.